The Process Manufacturing feature is a new Module / Function that works independently from the current Manufacture / Kitting Function found under the Inventory section In Palladium Enterprise. The feature will allow you to Create Jobs, Post Work in Progress in the form of Inventory, Service, Labour and Machinery costs that will remove the items from Stock and

post to the WIP Account. On Closing a Job, the total costs get removed from WIP and the finished Goods updated with the respective cost. Below is a list of the Setup and Processing features found in the Manufacturing Module.

A new Ledger Account needs to be assigned to manage the Work In Progress.

Settings have been added in the Company Options function to cater for Imports and the related posting of the WIP from Scales to eliminate any human error or intervention. In addition an option has been added to validate and allow / disallow the over or under issuing of inventory per Work Centre.

The Work Centre function allows you to create steps within the manufacture process with the ability to assign Inventory Items, Additional Costs, Machine as well as Labour Costs per Work Centre. In addition a Work Centre could act as a staging area for Quality Control or final commissioning. We also have the ability to track or report on Jobs per Work Centre. As an added value, manufacturing variances in the form of item issuances are managed on a per item, per work centre basis, allowing for greater analysis on efficiencies per stage of production.

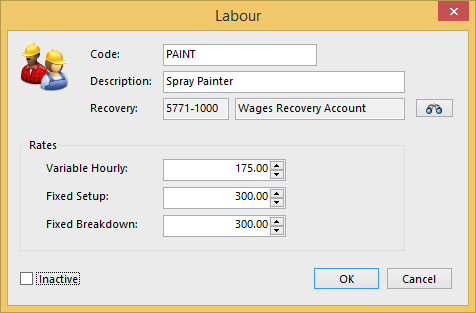

You can setup an unlimited number of Labour Types, each with their own rates and Recovery Accounts. When you setup the rates, the Cost will change proportionate to the quantity on the BOM. Ie should the BOM reflect a quantity of 100 and the variable hourly set at 2 hours, should a job be created to manufacture 1000 items, the variable costs will be 20 (2 / 100 x 1000) hours and the fixed Setup and Breakdown Costs at R300 respectively per the screen below.

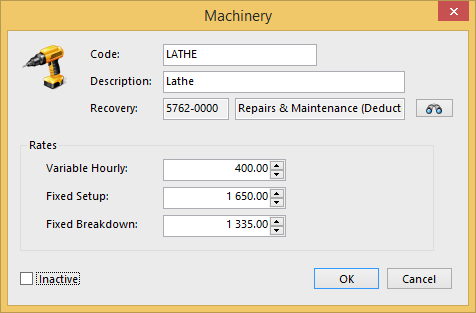

You can setup various Machine types and rates as we do with the Labour rates above, and assign these during the Process WIP process routine.

When you setup the BOM, you first define the item to be manufactured, then assign any By-Products that may be associated with this manufacture. Thereafter you will specify the different Work Centres (routing) for this Manufacture. Once you have defined your Operations (or Manufacture Steps), you then need to assign the relevant Inventory / Labour / Machinery / Recovery costs per Work Centre. In the example below you will see that we have selected the Machine Work Centre and the Components assigned to the Machine Work Centre.

Here we have allocated Labour to this Work Centre.

Here we have allocated Machine Time and Costs to this Work Centre.

We can optionally assign Recovery Costs to the process such as Electricity in large Engineering concerns.

The revision option allows you to maintain fill Bill Revisions/changes with the tracking on the revision date of the Job. This facilitates the recall or full recipe tracking of a manufactured item.

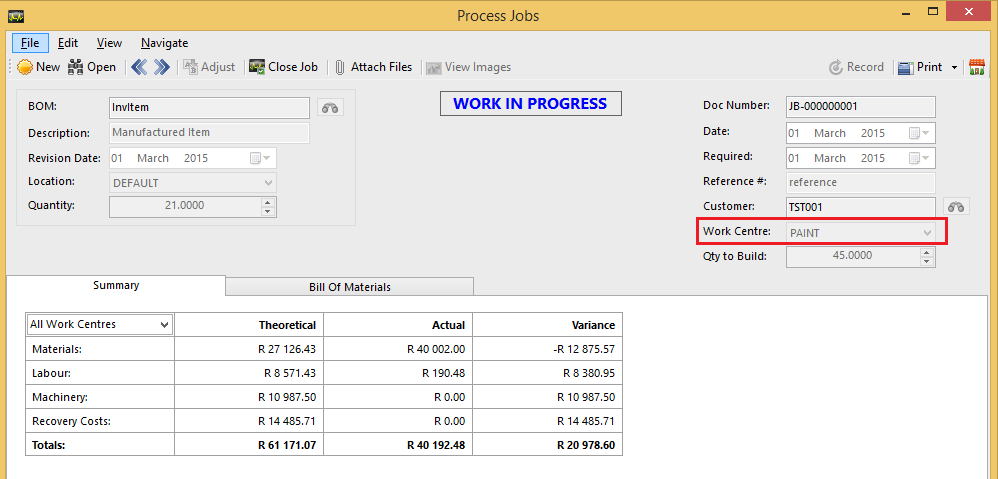

To create a job you need to go to the Process Jobs icon and select the Item that you would like to manufacture, as well as the Quantity to Manufacture. In our example below, the BOM was setup for a Manufacture Qty of 21, and we would now like to manufacture 45 items. What will happen is that all quantities as well as variable costs will change proportionately with Fixed Cost Components and Recovery Costs remaining the same.

We can optionally assign Recovery Costs to the process such as Electricity in large Engineering concerns.

On creation, the status of the job is “open”. At this stage, the Job can be adjusted and additional items or resources added or removed. Only when Inventory or resources have been issued to a Job, does the status change to Work in Progress at which time the Job is “Fixed” and unable to be amended.

At this stage the following reports can be printed from the Process Job Function:

Job Card – detailing all expected costs and resources assigned to the job by Workcentre

Pick Lists – Bulk Pick Lists per Workcentre – allowing you to prepare the inventory for issuing to the Job

We have also included a Cost Summary function that records the Actual vs the Theoretical costs on the BOM with the difference being a manufacturing variance that can be reviewed on an ongoing basis.

WIP can be posted as many times per Work Centre as required. The Issued column below will detail all previous issues for this item for the specific work centre. In addition to this, although the main Job cannot be amended, you can still assign any other Inventory Items or Resources to the Job (ie non-original BOM items) at any stage for substitution purposes. Such items will be highlighted on the Manufacturing Variance.

The Job Transfer function sets the “default” Work Centre for that job, allowing users to have a detailed view of what status of production or state that a Job is currently in.

You can also view the status of a Job via the Process Job Function below.

Job statuses can also be viewed through the Production Centre Calendar with the option to filter on the Job Status and / or Work Centre for extensive flexibility.

A job can be fully or partially closed. When a job is partially closed, because the final costs are not yet known at this stage, Palladium will use the Theoretical Manufacture costs for the transaction with the net over/under cost assignment being allocated when the job is fully closed.

In addition to the Reports Mentioned above, we also have the following comprehensive manufacturing reports to record costs and manage efficiencies within the production environment.

The Production Variance report will allow you to manage the actual quantity and costs of a Job vs the theoretical quantities and costs on a per Work Centre basis – allowing production manager the ability to identify production inefficiencies easily. This is extended to Inventory Items, Labour Resource, Machine Resources and even general Company Overhead allocations.

This report allows you to manage the theoretical output (quantity of manufactured items) vs the actual manufactured quantity.

This report allows you to manage the efficiency, or usage, of a Labour or Machine resource over a specific period.